| OCR Text |

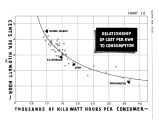

Show WATER FOR UTAH industries and for petroleum refining. In 1943, the consumption of caustic soda by such industries in the Western States was on the order of 34,000 tons. Consumption trends are definitely rising. Calcium carbide is used primarily for the generation of acetylene gas induced by the reaction of water upon calcium carbide. One pound of calcium carbide and one gallon of water will produce 4.5 cubic feet of acetylene gas. Minor quantities of calcium carbide are also used for the manufacture of calcium cyanamide - used as a base for melamine plastics, as a nitrogenous fertilizer and as a defoliating agent - and for the production of cyanides by the fusion of cyanamide, carbide and common salt, used in gold extraction and the manufacture of insecticides. Acetylene is important for oxy- acetylene welding and in recent years has become a principal base for numerous chemical industries. These include " neoprene" and " koroseal" types of synthetic rubber; acetaldehydes for the production of acetic acid and acetic anhydride used in acetate rayon manufacture for organic acetates; the production of chlorinated compounds and vinyl plastics. In general, calcium carbide is becoming one of the most important bases for the future growth of chemical industries. In 1946, the total United States production of calcium carbide was slightly under 600,000 tons, of which 27,000 tons was in the Pacific Northwest. During the war, the estimated consumption of calcium carbide in the eleven Western States was on the order of 50,000 tons consumed in the production of acetylene for welding purposes. It is possible that, in I960, the Western States may consume between 70,000 and 140,000 tons of calcium carbide annually. Of this market, Utah - by virtue of its favorable raw material oosition and its central geographic location - might share to a total of between 20,000 and 40,000 tons per year, provided adequate sources of low- cost power are available. In 1946, roughly five billion cubic feet of acetylene gas were generated in the United States. During war peaks, the production was almost seven billion cubic feet. Of these amounts, 60% was consumed in the manufacture of synthetics. Because of Utah's supply of raw materials and its central location with respect to other Western States, its potential acetylene generation would be primarily for chlorethylenes and synthetic rubbers. For instance, neoprene synthetic rubbers consumed about 40% of acetylene used for all synthetics in 1944. In this field, chlorine ( from salt) is an essential co- element of production. The establishment of chlorine, caustic soda and calcium carbide production, it can be readily seen, would provide a splendid foundation for diversified chemical manufacturing in Utah. The possibilities are primarily dependent on the availability of electric power. A minimum- sized chlorine and caustic plant, producing on the order of roughly 20,000 tons each of chlorine and caustic soda per year, would require in the neighborhood of 60,000,000 kilowatt- hours. A one- furnace plant for calcium carbide, producing about 20,000 tons per year, would likewise consume 60,000,000 kilowatt- hours. However, the same plant could be used to produce ferroalloys such as ferrosilicon and, therefore, might effectively provide Utah with production of both of these important industrial substances. Assuming electric power could be made available in sufficient quantities, the establishment of these plant units would further depend on the possibilities of balancing costs of power against costs of assembling raw materials and costs of marketing the end- products. The nearest competitive location of this industry - the Pacific Northwest - is supplied with extremely low- cost power and fairly inexpensive salt. Lime and coke, on the other hand, are relatively high in delivered price. It is not improbable, therefore, that considerably lower costs for all these raw materials in Utah might provide a favorable differential for power costs which cannot fail to be higher in level than those in the Pacific Northwest. The potentials are intriguing and worthy of consideration in the allocations of electric power to be developed in Utah's potential water development projects. There are many other chemicals which could be produced in Utah. The establishment of their production, however, cannot be adequately visualized without assurances of both water and power supplies in quantities far superior to those now available. ] |