| OCR Text |

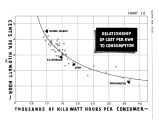

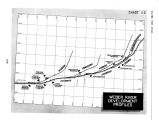

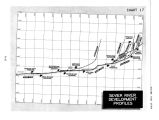

Show WATER FOR UTAH UTAH'S CHEMICAL INDUSTRIES ... The Resource Base ... ... Air ... Of the thirty- four basic materials required for the development of most important chemical industries, Utah possesses abundant quantities of all but a very few. In terms of relative importance, the chemical industry stresses water, air, coal, sulphur, salt and limestone. With these six basic raw materials, together with fuel and electric power, modern technology has wrought wonders of diversified production for a myriad of items, from the most commonplace to the rarest. Abundant and low- cost supplies of these materials, together with fuel and power, lay a foundation from which can spring a long list of chemical processing plants. Water and Power... Water is used in chemical industries for cooling and actual processing purposes. Requirements in terms of quantity, quality and even temperature vary from industry to industry. In some, the total amount of water flowing into a minimum- sized plant is staggering. In others, quantity may be secondary to purity in relative importance. Electric power is an important copartner of water. It is required for pumps, coolers and a variety of other electric motor- driven devices to carry and treat water and materials in the chemical plant. If is also of great importance in the electrolysis of water itself, breaking it down into constituent oxygen and hydrogen. Utah's existing water and power supplies are not now sufficient to provide the kind of opportunity for chemical industry establishment which its other raw materials would make possible. However, with the full development of water resources in the State, this situation can be satisfactorily resolved. The most striking use of air in chemical industry is for the extraction of its contained gases. By liquefaction - alternately compressing, cooling and expanding to the point where air becomes a very low- temperature liquid - and by fractional distillation, it can be made to release its nitrogen, oxygen, rare gases such as argon, neon and krypton. By passing a stream of air through an electric arc or through a suitable medium heated to extremely high temperatures, it can be made to shed its nitrogen content. Its more commonplace uses involve the blowing and dilution of gases, the supplying of oxygen ( as in the blast furnace and the Bessemer converter of the steel industry) and all other " air- conditioning" uses which seem too obvious to mention but without which a chemical plant could not operate. Electric power, as in the case of water, is an indispensable adjunct to the use of air in chemical industries. In air liquefaction, electricity is used to drive compressors and cooling systems. In the so- called arc process for the production of nitrogen, it provides the energy for the arc. For the blowing, compressing, cooling and circulation of air in all chemical processes, electric power drives the motors. Coal... Coal is probably the most versatile of all chemical raw materials. As a source of fuel, it provides heat necessary in chemical processes. As carbon, it is indispensable in many metallurgical industries. When heated under controlled conditions, it becomes the base of a fabulous family of chemicals: its gas, aside from fuel value, is a rich storehouse of benzol, toluol, xylol, sulphur and others; its carbon residue - either a char or a coke depending on the type of coal and pro- F641 |