| Title |

The Selective Non-Catalytic Reduction SNCR Process: Experience with the Exxon Thermal DENOx Process at Two Circulating Fluidized Bed Boiler Commercial Applications |

| Creator |

Bodylski, J. A.; Hass, G. A. |

| Publisher |

University of Utah |

| Date |

1992 |

| Spatial Coverage |

presented at Cambridge, Massachusetts |

| Abstract |

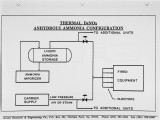

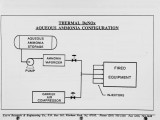

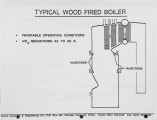

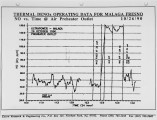

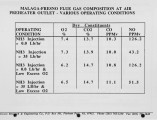

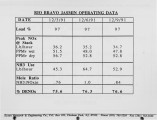

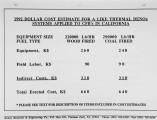

Within this paper and presentation, information will be presented on the technology & applications experience of the Exxon THERMAL DENOx Process. Specifically, details are given for two circulating fluidized bed boilers which have been operating for more than 2 years while achieving between 65% and 75% NOx reduction for wood and coal fuels. Since no catalyst is necessary to assist in the reduction of Nitrogen Oxide in the flue gas with Ammonia, the THERMAL DENOX Process is classified as a Selective Non-Catalytic Reduction (SNCR) post-combustion NOx control technology. Over 125 commercial installations of the Exxon THERMAL DENOx Process have been designed, installed and operated since 1975. Recent developments of interest include operation with aqueous ammonia as well as anhydrous ammonia. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6hh6npf |

| Setname |

uu_afrc |

| ID |

12214 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6hh6npf |