| Title |

Measurement of Air Toxics in Engine Exaust Using Fourier Transform Infrared (FTIR) Spectroscopy |

| Creator |

LaCosse, Jeffrey P.; Ogle, Larry D.; Shareef, Gunseli Sagun; McCarthy, James M.; Evans, James M. |

| Publisher |

University of Utah |

| Date |

1995 |

| Spatial Coverage |

presented at Monterey, California |

| Abstract |

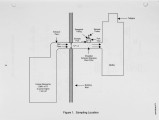

In response to the 1990 Clean Air Act Amendments, the Gas Research Institute (GRI ) is investigating emissions of air toxics from natural gas industry sources. Included in this effort are measurements from internal combustion engines, one of the source categories targeted by U.S. Environmental Protection Agency (EPA) for development of Maximum Achievable Control Technology (MACT) based regulations by the year 2000. Formaldehyde and other aldehydes are the air toxics potentially present in engine exhaust. Since there were no EPA-validated measurement methods available for quantifying aldehydes, GRI initiated a test to validate an extractive Fourier Transform Infrared (FTIR) method for measurement of these species according to EPA Method 301 - Field Validation of Pollutant Measurement Methods for Various Media. In addition to formaldehyde, acetaldehyde and acrolein, other compounds (i.e., oxides of nitrogen, carbon monoxide, carbon dioxide, and moisture) were also validated be cause FTIR is capable of measuring multiple species on a continuous and realtime basis. The results of this validation testing have been reviewed by EPA, and in a July 21, 1995 letter from EPA, the method has been approved for gas-fired equipment. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6xg9tqg |

| Setname |

uu_afrc |

| ID |

9592 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6xg9tqg |