| Title |

Combustion Techniques in Remote CC-HDR Process |

| Creator |

Onoda, Masami; Okimori, Mayumi; Takikawa, Iemitsu; Ikezaki, Eiji; Hiramoto, Yuji |

| Publisher |

University of Utah |

| Date |

1991 |

| Spatial Coverage |

presented at Honolulu, Hawaii |

| Abstract |

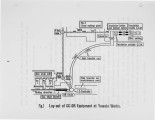

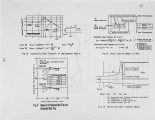

The remote CC-HDR process went into operation at Yawata Works, Nippon Steel, in June 1987. The new process is an advanced version of the proximate CC-HDR process in which the continuous caster is located adjacent to hot rolling mill, as represented by Nippon Steel's Sakai Works. In this remote CC-HDR process, the new insulater with the luminous wall burners and the slab edge heater by the jet gas impinging were developed and installed in order to keep the slab edge temperature high enough to be rolled at the hot strip mill. These important combustion technologies that made great contributions to the realization of the remote CC-HDR process are described. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6tb19fb |

| Setname |

uu_afrc |

| ID |

7387 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6tb19fb |