| OCR Text |

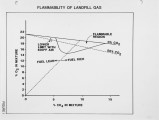

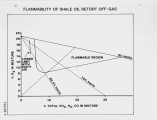

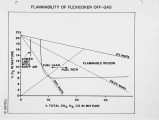

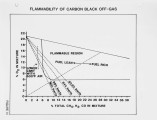

Show WASTE GAS FIRING IN PROCESS HEATERS AND BOILERS the same fuel rate. This means that for the four fuels being considered the flue product pressure losses may be from 1.18 to 6.78 times greater than the losses normally experienced with conventional fuels. Careful attention must be given to the flue gas pressure losses, especially if a unit is being retrofitted to burn alternate fuels. HEAT TRANSFER Use of alternate fuels will affect both radiant and convective heat transfer. Table II gives a comparison for the adiabatic flame temperatures, assuming the fuels can be combusted without supplementary firing, for each of the four fuels. The adiabatic flame temperatures range from 1390°F for the carbon black off-gas to 2990°F for the landfill gas. Adiabatic flame temperature for conventional fuels firing with 15% excess air is in excess of 3200°F. Since radiant transfer for constant emissivity is proportional to the fourth power of the absolute temperature, it is obvious that because of the low temperature combustion of the alternate fuels, radiant transfer will be drastically reduced per square foot of transfer area. The degree of reduction in radiant transfer will also depend on the change in emissivity. The emissivity of the gases is primarily determined by the partial pressure of the (XL and H„0. Depending on the composition of the inert components, the emissivity may be either greater or less than the emissivity of the flue products from a conventional fuel. In general, convective heat transfer will be greater than the convective transfer for a conventional fuel in a given unit since flue product velocities will be greater. The degree of increase in convective transfer will depend on the temperature of gases entering the convective transfer section. FLAMMABILITY Well defined calculation procedures can be used for design of a combustion/heat transfer system that compensates for all of the design considerations that have been discussed to this point. One of the most important points that must be considered is the effect of the inert components in the fuel on the ability to burn the fuel. When an alternate fuel is being considered, determination must be made as to whether it is even theoretically possible to burn the fuel. This can be determined with some degree of confidence by using flammability diagrams and past experience. Figures I through IV are flammability diagrams for the four fuels discussed. Figure I is the diagram for methane, diluted with (XL, which is the case for landfill gas. Operating lines are shown for pure methane (0% (XL) and a mixture of 50% methane and 50% (XL. With 60°F fuel and air temperature, the limits of flammability for pure methane range from approximately 5.3% by volume to 14% by volume. The limits expressed, assume a perfect mixture of fuel and air with no heat transfer. Since burners do not mix the fuel and air perfectly, the actual flammability limits will vary depending on the burner used. For example, the lower limit of flammability for a burner, based on total air flow is usually lower than the limit given by the chart since 1.1.3 |