| Title |

Progress in Development of the Burner Engineering Research Laboratory |

| Creator |

Payne, R.; Cole, Jerald A.; Samuelsen, G. S.; Sowa, W. A.; Dunn-Rankin, Derek; Fornaciari, Neal; Carling, R. W.; Gemmer, R. V.; Kezerle, James A. |

| Publisher |

University of Utah |

| Date |

1992 |

| Spatial Coverage |

presented at Cambridge, Massachusetts |

| Abstract |

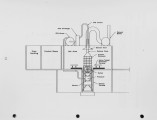

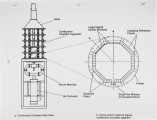

The Gas Research Institute, and Sandia National Laboratories have established a Burner Engineering Research Laboratory (the BERL) at Sandia's Combustion Research Facility in Livermore California. The BERL is designed as a highly flexible facility for the study of natural gas combustion in burners. Having access to a comprehensive range of state-of-the-art laser diagnostics at Sandia, the BERL is ideally suited to fundamental analysis of applied problems and issues. Inauguration of the BERL is expected upon its completion in summer 1992. The BERL includes a 650 square-foot laser diagnostics laboratory with support equipment for the firing of industrial-scale gas burners from 100 MBtu/h to 3 MMBtu/h. Burners are housed in an up-fired combustion chamber with octagonal cross section. The combustion chamber is 42 inches In diameter and nominally 5 feet high. Removable, interchangeable panels on each of the octagonal faces provide optical access for laser diagnostics, and can accommodate insulated refractory or water-cooled walls for a range of thermal environments. Both the combustion chamber and the optical diagnostic equipment are translated in space so that the optical sampling volume can be positioned anywhere within the furnace. This permits flow-field mapping, as well as point temperature and chemical composition measurements. Available diagnostics include standard laser-based techniques such as Laser Doppler Velocimetry (LDV), Laser-induced Fluorescence (LIF), and Mie Scattering. More advanced analytical methods include Coherent Anti-Stokes Raman Spectroscopy (CARS) and Degenerate Four-Wave Mixing (DFWM). Capabilities and operational specifications, as well as plans for operation and verification of the BERL are discussed. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s66w9dpp |

| Setname |

uu_afrc |

| ID |

12963 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s66w9dpp |