| Title |

A Laboratory-Scale Furnace to Study Ash Deposition and Fouling Due to Pulverized Coal Combustion |

| Creator |

Floris, F.; Pasini, S.; Partesotti, C.; Quattroni, G. |

| Publisher |

University of Utah |

| Date |

1988 |

| Spatial Coverage |

presented at Pittsburgh, Pennsylvania |

| Abstract |

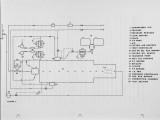

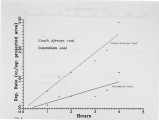

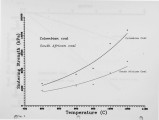

A refractory lined furnace rated at 20 Kg/h of coal, fuel oil or gas was built for testing small-scale pulverized coal burners and collecting ashes from flue gas. Operation of the rig provides the control over combustion paramaters as temperature, fuel, primary and secondary air rate and flue gas velocity. Ash samples are collected in a square cross test section where air cooled deposition probes are inserted. Lateral ports allow video-camera records on ash deposi tion rate. The work presented here is part of a research program designed to gain a better understand i ng of mineral matter behaviour during combustion and the effect of composi tion and combustion parameters on fouling. A Colombian and a South African coal was used under different combustion conditions and ash samples were collected, analyzed and their compression strengh evaluated and compared with different coal sintering strength data. Few polished sections were prepared and analized with x-ray and microscope in order to characterize the surface state and composition on a microscale. This paper will present the results of work performed to determine composition and adhesive strength of ash particle that form deposits on superheater tubes, under the strictly controlled combustion, fluid dynamic and heat transfer parameters of test furnace. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6765hwh |

| Setname |

uu_afrc |

| ID |

5112 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6765hwh |