| Title |

Development and Demonstration of the Low NOx StAR Burner for High Temperature Industrial Furnaces |

| Creator |

Benson, Charles; Thijssen, Johannes; Loftus, Peter; Moreland, Don; Moore, Ed; Irwin, Bruce; Gemmer, R. V.; Lingras, Anil; Swistock, Harry |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Maui, Hawaii |

| Abstract |

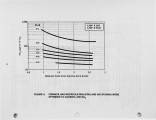

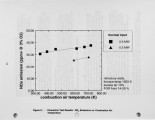

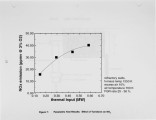

High temperature furnaces in the metals industry present a significant challenge for effectively controlling NOx emissions, especially when combustion air is preheated for increased thermal efficiency. Such facilities are now being affected by environmental regulations that require reductions in NOx emissions. Thus, it is becoming increasingly important to cost-effectively control NOx emissions from these facilities. For these reasons, a team consisting of Arthur D. Little, Hauck, and MIT with support from the Gas Research Institute has undertaken the development and demonstration of an innovative, low-NOx, natural-gas-fired burner for high temperature industrial furnaces. This work has produced a burner that utilizes both staged air supply and flue gas recirculation to effectively suppress NOx formation. The burner is able to attain NOx emissions of 25 - 50 ppm and CO emissions below 50 ppm when operating with 700 K (800°F) combustion air in a furnace having an operating temperature of 1280 - 1560 K (1850 - 2350°F). Furthermore, temperature uniformity measurements in a forge furnace demonstrated heat transfer performance superior to that of conventional burners used in this industry. A new line of burners based on this technology, spanning a firing rate range of 0.3 - 6 MW (1 - 20 MMBtu/hr) will be introduced by Hauck during 1995. This paper describes the demonstration of two 0.6 MW (2.0 MMBtu/hr) burners in a forge furnace owned and operated by Schlosser Forge in Cucamonga CA. Key activities included: scaling of the prototype design to the required field burner size; refinement of the design through testing under controlled conditions at the GRI/DOE Burner Engineering Research Laboratory; installation and start-up of the burners at Schlosser; and monitoring of emissions, efficiency and product quality over a wide range of furnace operations. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6qr50rc |

| Setname |

uu_afrc |

| ID |

9890 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6qr50rc |