| Title |

Development and Testing of the MIT-RSFC Low-NOx Coal Combustor for the B &W LEBS Program |

| Creator |

Beer, J. M.; Barta, L. E.; Lewis, P. F.; Wood, V.; Akinyemi, O.; Haynes, J.; Jimenez, J.; Manurung, R.; Rodgers, L. W. |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Maui, Hawaii |

| Abstract |

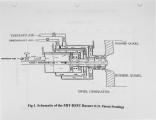

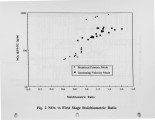

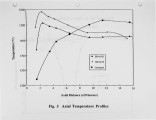

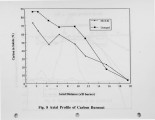

MIT as a partner with Babcock & Wilcox, a McDermott Company in the USDOE sponsored Low Emission Boiler System (LEBS) program has performed an experimental analytical and experimental effort to refine and define the operational characteristics of the MlT Radially Stratified Flame Core (RSFC)Burner for the combustion of pulverized coal. The RSFC has been previously developed to a very promising state for natural gas and to a lesser extent for heavy fuel oil2 firing. In this effort the burner was operated at a nominal firing rate of 5 mm Btu/hr on lllinois #6 coal. NOx, CO and unburned carbon emission data have been collected and analyzed for a wide range of conditions. Burner performance has been evaluated as a function of burner settings, firing rate, air equivalence ratio, air preheat, transport air to coal ratio and excess air. For selected conditions, detailed in flame measurements of gas composition, temperature, and velocity as well as solids concentration and composition have been performed. These data can be used for detailed analysis and modeling studies. The performance of the burner was found to be superior to the expected results. The burner was extremely stable, and relatively insensitive to operating conditions. NOx levels below 100 ppm with carbon burnout greater than 99% were achieved. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s64170pq |

| Setname |

uu_afrc |

| ID |

9847 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s64170pq |