| Title |

Modifications on Front Fired Pulverized Coal Fuel Burners |

| Creator |

Owens, Brad; Hitchko, Michael; Broderick, R. Gifford |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Maui, Hawaii |

| Abstract |

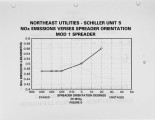

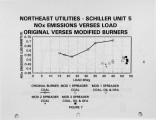

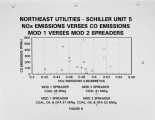

Burner optimizations and modifications were done on Northeast Utilities Schiller Unit No.5. This is a Foster-Wheeler 52 MWg pulverized coal and No.6 fuel oil-fired boiler with six burners. The burner optimizations consisted of fuel and air balancing. Burner modifications consisted of the addition of staged coal flame stabilizers, new coal spreaders, and modifications to the existing burner pulverized coal pipe. NOx emissions of .42 Ib/mmBtu were achieved at 41 MWg with all burners in service and without the use of overfire air or bias firing. This represented approximately a 40% NOx reduction from the average baseline NOx emissions of .7 lb/mmBtu prior to the optimizations and burner modification program. There was no increase in LOIs which ranged between 20-35%. Furnace excess O2 of 1.25% was achieved with CO emissions of less than 200 ppm. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s69p348k |

| Setname |

uu_afrc |

| ID |

9546 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s69p348k |