| Title |

Measurement of Organic Air Toxics Emissions from Coal Firing in a Laminar-Flow Reactor |

| Creator |

Nsakala, N.; Raymond, D.; Patel, R.; Cohen, M. |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Maui, Hawaii |

| Abstract |

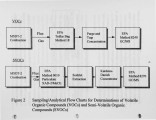

Title III of 1990 Clean Air Ad Amendments (CAAA) addresses the emissions of 189 Hazardous Air Pollutants (HAPs), also referred to as "air toxics." Through this, Congress mandates the Environmental Protection Agency (EPA) to conduct risk assessment studies on the health hazards associated with HAPs before promulgating any legislation for their control. In order to meet the potential future needs of industry resulting from air toxics emissions regulation, Combustion Engineering, Inc. (ABS CE) has been conduding a multi-faceted R&D program aimed at clarifying the impads of fuel properties, fumace design and operating conditions on air toxies emissions. This paper presents some of the organic air toxies (Volatile OrganiC Compounds, Semi-Volatile Organic Compounds and Poly-cyclic Aromatic Hydrocarbons-VOCs, SVOCs and PAHs) results from combustion testing of a bituminous coal in a three-stage entrained flow reador. The reador is capable of heating readant particles to temperatures of up to 2650 OF and sustaining particle residence times of up to about 1.5 seconds to simulate the rapid suspension firing conditions encountered in pulverized-a>al fired boilers. The various measurement and analytical techniques used in the testing program are identified and the results obtained are discussed. Results obtained from this study indicate that coal combustion does result in the emissions of some organiC HAPs at low levels. Results also show that low NOx firing does not necessarily exacerbate the emissions of these micro-pollutants. Furthermore, the emissions levels determined were quite low as compared to US EPA's MACT stipulations. It should be borne in mind that metal emissions (Hg, Se, As, Pb, etc.), which are likely to be greater, were not part of this investigation. Lastly, testing in larger-scale facilities is essential so that linkages between field and laboratory results can be established. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6bp05b2 |

| Setname |

uu_afrc |

| ID |

9420 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6bp05b2 |