| Title |

Emission Control of Small Fluidized Bed Combustors Utilizing Biomass Fuels |

| Creator |

Bell, Arlen W.; Haythornthwaite, Sheila M.; Sanders, Charles F.; Bray, A. Philip |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Maui, Hawaii |

| Abstract |

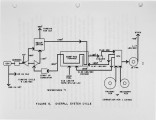

The use of biomass fuels for power generation and process hot water and steam is an important aspect of cultural and economic development of many Pacific Rim countries, even including portions of some technologically advanced countries. Much of this biomass will be burned in relatively small combustors of the order of one to ten million Btu per hour in fluid bed combustors. While there is significant emission potential with biomass fuel, the relatively small size of the equipment provides certain advantages in obtaining adequate emission control. The specific design of a 3 million Btu per hour fluid bed combustor is described, and items such as furnace sizing, cyclone selection, and back end treatment of the flue gas is discussed. This particular application is to provide high temperature heat to an "externally fired" gas turbine for power generation (200 lew net), with optional waste heat available for steam, hot water heating or steam driven chillers. The unit described is being installed in a lumber mill in Georgia (USA) for EPA evaluation, and several others are being considered for installation in the Caribbean and Pacific islands areas. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6833vn1 |

| Setname |

uu_afrc |

| ID |

8742 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6833vn1 |