| Title |

Optimization of the Low NOx Industrial StAR Burner at the Burner Engineering Research Laboratory |

| Creator |

Thijssen, Johannes H. J.; Benson, Charles; Fornaciari, Neal; Schefer, Robert; Irwin, Bruce; Carpenter, Rick; Sanford, Robert; Claytor, Lloyd |

| Publisher |

University of Utah |

| Date |

1994 |

| Spatial Coverage |

presented at Kingston, Canada |

| Abstract |

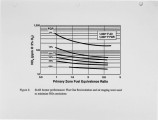

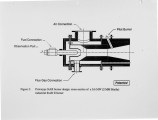

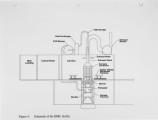

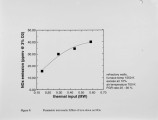

Since 1990, Arthur D. Little (ADL) , in cooperation with the Massachusetts Institute of Technology (MIT) and Hauck Manufacturing Company, and under sponsorship of the Gas Research Institute, has developed the advanced low NOx Staged Air Recirculating (StAR) burner concept for application in high temperature industrial furnaces. The program goals were to reduce NOx emissions to below 150 ppm (@ 3% 02) , while maintaining the CO emissions below 100 ppm. These emission levels are to be achieved with air temperatures ranging from ambient temperature to 1100 K (-1500 F). Of course, the burner should demonstrate excellent furnace operating characteristics (including product quality, productivity, efficiency and tum-down capacity) at a price comparable to that of conventional burners. The target market of such burner technology lies predominantly in the materials processing industry, with applications such as forging, heat treating, aluminum melting, steel reheating and glass melting. The burner concept incorporates both s e l f entrained flue 'gas' recirculation and a staged air supply to minimize NOx and CO emissions at high furnace temperatures. After the initial concept development by ADL and MIT, a 0.9 MW (3 MM Btu/hr) laboratory prototype of the StAR 'burner was designed using both fluid dynamic and chemical kinetic modeling. The prototype burner was then fabricated by Hauck and tested at MITs Combustion Research Facility [1]. Based on these successful initial tests, a 0.6 MW (2 MM Btu/hr) field demonstration prototype, the StAR IT burner, was developed. Two StAR II burners were installed at the Schlosser Forge Company (Cucamonga, Ca), a market leader in the manufacture of high performance metal parts for the aviation and aerospace industry, for a field demonstration. This version of the StAR burner uses 725 K (800 F) combustion air. Simultaneously, an identical StAR II burner was installed at the Burner Engineering Research Laboratory for further optimization and detailed burner characterization. … |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6x069mz |

| Setname |

uu_afrc |

| ID |

8117 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6x069mz |