| Title |

Performance Characteristics of a Hot-Wall Furnace Fired With Coal Water Slurry (CWS) Using Gas/Air Atomization |

| Creator |

Li, Zongwen; Han, Kyu-il; Essenhigh, Robert H. |

| Publisher |

University of Utah |

| Date |

1983 |

| Spatial Coverage |

Akron, Ohio |

| Abstract |

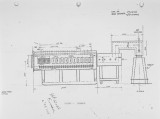

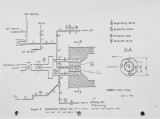

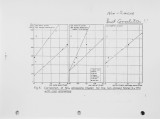

CW slurries atomized with a gas/air mixture have been burned in a hot wall furnace of dimensions from 600 mm x 600 mm x 3 m to determine the feasibility and influence of gas atomization. The furnace has 30 water cooled tubes on the floor to provide a thermal load and to obtain heat flux profiles. Three different slurries were used of similar composition. The results were mainly evaluated by use of the Furnace Performance equations that yielded the Firing and Efficiency curves and relevant curve coefficients. The slurry combustion results were compared with Performance curves obtained using #1 oil. In preliminary experiments 9 different nozzles were tested; a Delavan pintle-type gave the best results. Problems encountered with the others included: blockage, inadequate turn-down, flame instability, poor atomization, or overall poor performance. The gas markedly aided flame stabilization. In a very hot furnace stabilization without gas was possible, but the window of stability was increased with the co-use of gas. With low swirl, generating a long narrow flame, gas co-firing is believed to be necessary. The quantitative results showed a significant effect of excess air, but no evident effect of slurry type; however, there did seem to be an effect of slurry type on NOX and SOX levels: levels of both were generally low, in the range of 200 to 650 ppm. The slurry generating the higher NOX levels also yielded the lower SOX levels, and vice versa. At the higher levels, the conversion of S to SO appeared to be quantitative. Thermal efficiencies ranged from 15 to 30% with the slurries, but were over 40% with oil. The difference was unexpected and has not yet been explained. It is not thought to be due to ash deposition. The difference is in agreement, however, with slurry firing data at high gas rates (50% on a thermal basis) which otherwise showed "anomalously" high thermal efficiencies compared with the slurries without gas or with low gas fractions. Nevertheless, the results clearly show the potential value of co-firing gas with the CW slurries. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6jq13kz |

| Setname |

uu_afrc |

| ID |

127 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6jq13kz |