| Title |

Full-Size Characterization of Low-NOx Burner Coal Nozzle Mixing Devices in a 100 MBtu/hr Research Facility |

| Creator |

Sarv, Hamid; LaRue, Albert D. |

| Publisher |

University of Utah |

| Date |

1995 |

| Spatial Coverage |

presented at Monterey, California |

| Abstract |

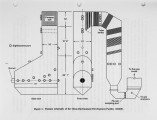

Reduction of unburned carbon levels for coal burning power plants that are equipped with 10w-NOx burners decreases fuel costs, and facilitates fly ash recycling and disposal. For this purpose, Babcock and Wilcox (B&W) has developed a proprietary coal nozzle mixing device to install in commercial low-NOx pulverized coal (PC) burners. Combustion and emissions performance of a full-size, 100 million Btu/hr (MBtu/hr), DRB-XCL® 10w-NOx PC burner and the proprietary device was characterized in the Clean Environment Development Facility at B&W with four different fuels ranging from subbituminous to low volatile bituminous coals. Experimental parameters included coal fineness, excess air, and thermal load. Relative to the baseline 10w-NOx burner, the coal nozzle device produced shorter flames and lower unburned carbon levels, while maintaining low NOx emissions. Retrofit plans for commercial installations are underway. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s61v5hjq |

| Setname |

uu_afrc |

| ID |

7537 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s61v5hjq |