| Title |

Achieving Ultra-Low Sulfur Levels in Refinery Fuel Gas |

| Creator |

Brown, Lynn D. |

| Publisher |

University of Utah |

| Date |

1991 |

| Spatial Coverage |

presented at Honolulu, Hawaii |

| Abstract |

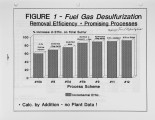

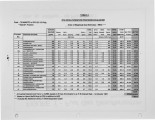

A study was performed to provide the Western States Petroleum Association (WSPA - Los Angeles refiners) with both technical and cost information on "state of the an" hydrocarbon fuel gas desulfurization processes. This report served to formulate WSPA's input to South Coast (LA) Air Quality Management District's (SCAQMD) proposed control measure F-2 to regulate the total sulfur content in gaseous fuel. The following tasks were performed in preparing this report: • An assimilation of existing refinery fuel gas data and operating data from the existing desulfurization systems. • A literature and commercial practice survey of hydrocarbon fuel gas desulfurization technologies. • The development of a "typical" refinery base case for fuel gas before and after existing treatment from WSPA member data. The solicitation of performance and cost quotations from vendors based on this generalized refinery base case. • The conceptual development of potential process schemes to achieve various levels of fuel gas desulfurization. • The estimation of the removal efficiencies and the annualized total costs (per unit of sulfur removed) of various proposed process schemes relative to each other. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6d79dzk |

| Setname |

uu_afrc |

| ID |

7100 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6d79dzk |