| Title |

The Use of Oxygen for Transient Incinerator Puff Reduction: Control Strategy and Field Results |

| Creator |

Ho, Min-Da |

| Publisher |

University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

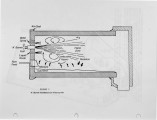

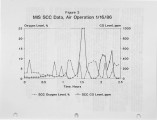

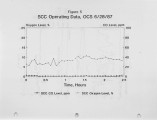

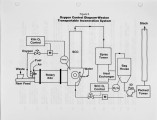

This paper reports on the field experience with a novel method for the enhanced control of transient emissions for rotary kiln incinerators using oxygen enrichment. When high-heat-content wastes are fed into rotary kiln incinerators in an intermittent mode (typical of ram feed systems), the transient combustion behavior of these materials creates unsteady releases of combustible gases which may momentarily deplete the oxygen content of kiln gases. These temporary oxygen-deficient conditions could cause the release of products of incomplete combustion (PICs). Release of PICs from incinerators has raised public concern and has been the subject of research projects sponsored by the EPA. Enhanced control of transient emissions was demonstrated by the field operation of the EPA Mobile Incineration System (MIS) at the Denney Farm Superfund Site in McDowell, Missouri. During this operation, large quantities of high-heat-content materials were burned periodically. These materials were ram-fed into the rotary kiln. To respond to the transient oxygen demand that resulted from the burning of these materials, a unique oxygen feedforward-feedback control logic was designed into the LINDE® Oxygen Combustion System (OCS) which was retrofitted into the MIS in 1987. After implementation of the OCS, transient upset conditions were significantly reduced in the operation of the MIS. Low NOx emissions were also achieved. Additional field experience has also been obtained in the operation of Weston's Transportable Incineration System (TIS). Transient emissions were significantly reduced in the operation of TIS with the use of LINDE Oxygen Lancing System (OLS), while significant throughput was obtained. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6cj8h2k |

| Setname |

uu_afrc |

| ID |

6183 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6cj8h2k |