| Title |

Low NOx Combustion with Natural Gas |

| Creator |

Neff, Glenn C. Sr.; Joshi, M. L.; Tester, Marvin E.; Panahi, Sherry K. |

| Publisher |

University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

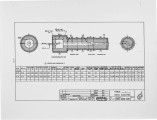

| Abstract |

An improved method of gas firing on a glass furnace and reduced NOx emissions is outlined. This method involves the use of a cracker for NOx reduction. The cracker method of gas firing takes about 25% of the furnace natural gas consumption through a separate cracker to produce soot particles. This is then re-blended with the balance of 75% of gas, producing a "soot-rich" gas mixture. The combustion of soot-rich gas produces flame with increased luminosity and lower adiabatic flame temperature characteristics which is expected to reduce NOx emissions by 35% or more. Past, current and future plans involving the cracker program are discussed. Past experiments on a pilot unit indicate a very low soot yield (-2%) due to undesirable reforming reactions. Current and future cracker design includes a new modulative gas cracker concept that incorporates several new features which enhance thermal cracking with very little reforming. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6rv0r8n |

| Setname |

uu_afrc |

| ID |

6128 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6rv0r8n |