| Title |

Meeting SCAQMD Rules 1109 and 1146 with Low NOx Burners |

| Creator |

Waibel, Richard T.; Napier, S.; Arledge, W.; Method, W. |

| Publisher |

University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

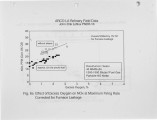

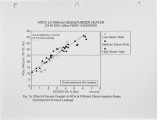

As reported previously, low NOx burners employing fuel staging combined with flue gas recirculation (FGR) have been developed to meet the strict emissions regulations mandated by the South Coast · Air Quality Management District (SCAQ11D) which oversees the Los Angeles area air basin. Specifically addressed have been Rille 1109 which effects existing process heaters over 40 million Btu/hr heat input in refineries and chemical plants and Rule 1146 which effects process heaters 40 million Btu/hr and less. Rille 1109 limitS emissions from the larger heaters to 0.03 lb of NOx per million Btu (approximately 25-28 PPM depending on fuel composition) and Rule 1146 limits emissions of the smaller heaters to 40 PPM (0.05 lb/MBtu). |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6q242tt |

| Setname |

uu_afrc |

| ID |

5855 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6q242tt |