| Title |

Demonstration of Radian's Patented Hybrid Low NOx Process |

| Creator |

Bell, Ronald D. |

| Publisher |

University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

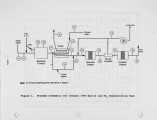

Radian Corporation has successfully completed demonstration testing of its patented Hybrid Low NOx Cogeneration Process for a diesel application. The process reduces NOx to levels below 25 ppmv and CO to below 50 ppmv by utilizing an oxygen "burnout" step, a catalytic reduction step, and a catalytic oxidation step. In the reducing step, 1 to 5% excess fuel is fired in an afterburner at 2000 to 2500 F. Firing in the reducing mode results in essentially no oxygen leaving the high temperature zone of the afterburner; the CO and H2 formed here reduce NOx across the reduction catalyst. Excess CO and H2 are oxidized across the oxidation catalyst. Advantages of Radian's Hybrid Low NOx Cogeneration Process over currently available NOx reduction technologies include the following: NOx reduction to levels below 25 ppmv with destruction efficiencies of 99+% achievable; requires only fuel gas and ambient air for NOx reduction; can be readily retrofitted to conventional combustion processes; does not require ammonia or urea injection; and increases overall energy conversion efficiency because of low excess air requirements. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6tt4thd |

| Setname |

uu_afrc |

| ID |

5838 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6tt4thd |