| Title |

Physical and Heat Transfer Modelling of a 200MW Thermal Corner Fired Boiler |

| Creator |

Jenkins, B. G.; Bertrand, C.; Dhanjal, S. K. |

| Publisher |

University of Utah |

| Date |

1989 |

| Spatial Coverage |

presented at Short Hills, New Jersey |

| Abstract |

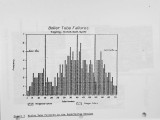

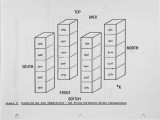

The effect of fuel changes on boiler performance and efficiency can be a major factor influencing the conversion potential of integrated process plant. Converting a 200MW corner fired water tube boiler from heavy fuel oil to natural gas can result in a 5-10% derating due to reduced radiant energy transfer, which would in turn reduce process capacity by a similar amount. As part of an assessment study to convert an alumina (Bayer Process) plant from heavy fuel oil to natural gas, an extensive physical and mathematical modelling project has been carried out to investigate and improve boiler performance to maintain MCR. A physical model of the boiler and associated ductwork has been used in both water and air modelling modes to equalize burner air distribution through the installation of air ductwork flow distributors, straightners etc; and to assess the effects of burner positions, angles, etc. on the radiant section aerodynamics. Results indicated an original maldistribution of air between individual burners of + 8%, which limits the boiler operation to 10-15% excess air conditions. By suitable air balancing the variation can be reduced to +2%, enabling 5% excess air condition to be achieved, with the attendant fuel savings that would ensue. The effects of burner angles on the radiant section aerodynamics can improve the heat transfer in the boiler by increased convection and gas residence time. Air modelling, to provide quantitative mass/momentum transfer data, together with a zone model matrix of 20 gas zones and 48 surface zones to simulate radiant and convective transfer, has been used to optimize the gas burner(s) design and position to give maximum radiant section efficiency in the boiler, and thus mitigate the effects of changing fuel. This novel, combined modelling approach to the study of new plant, and the conversion of existing plant is shown to be an inexpensive, reliable and important tool that can be used in combustion plant engineering design. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6br8vrf |

| Setname |

uu_afrc |

| ID |

5787 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6br8vrf |