| Abstract |

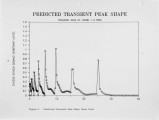

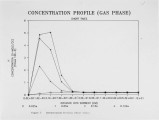

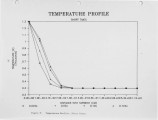

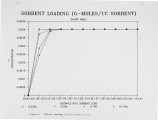

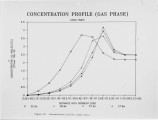

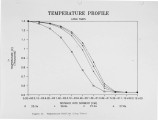

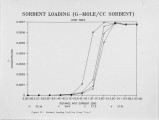

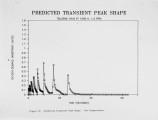

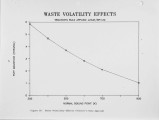

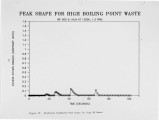

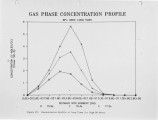

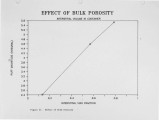

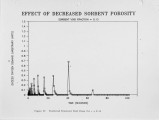

When containerized liquid wastes, bound on sorbents, are introduced into a rotary kiln in a batch mode , transient phenomena involving vaporization of the waste, a nd mass and heat transfer into the sorbent can allow a rapid release of waste vapor into the kiln environment, a displacement of excess oxygen from the primary flame , and formation of a "puff". This transient puff then travels to the afterburner and, if it is too large, can result in a failure mode of the incinerator system. Previous experimental work by the U.S. Environmental Protection Agency on a specially designed Rotary Kiln Incinerator Simulator has shown that, for liquid wastes, puffs are very easily generated, and that their magnitude and intensities increase with increasing kiln temperature and increasing kiln rotation speed. This paper provides insight into why this is so, and how the generation of puffs in general is controlled by waste properties, sorbent properties, and kiln operating parameters. A theoretical model describing simultaneous heat and mass transfer into a sorbent aggregate, coupled with vapor pressure driven waste vaporization within the sorbent aggregate, was combined with a fragmentation model and was able to qualitatively predict experimentally observed effects relating to puff duration, kiln rotation speed, kiln temperature, and stoichiometric oxygen requirement of the waste. The conservation equations in the model were solved numerically using a novel finite difference technique involving unequally spaced grid points, and a fully implicit algorithm. Fragmentation of the sorbent aggregate followed the size dependent relationship proposed by Austin, and also depended on kiln rotation speed. Extrapolation of the model to conditions beyond the experimental test matrix indicated very strong influences of waste boiling point (and consequently latent heat) , and of sorbent parameters such as overall void fraction in the container and the sorption characteristics of the individual sorbent particles. The model did not predict a first order effect of container dimensions, provided that other relevant sorbent parameters, such as overall void fraction, were kept constant. These theoretical results support the data from the EPA Rotary Kiln Simulator and suggest that the experimentally observed phenomena have general practical validity. Furthermore, the model can be used to rank wastes and sorbents with respect to their propensity to produce puffs. |