| Title |

Potential of PFB and AFB Packaged Industrial Boilers |

| Creator |

Fox, E. C.; Graves, R. L.; Kahl, W. K.; Thomas, J. F. |

| Publisher |

University of Utah |

| Date |

1982 |

| Spatial Coverage |

presented at Newport Beach, California |

| Abstract |

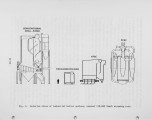

Industry is the largest energy consuming sector of our economy. It is the largest user of natural gas and a large consumer of oil. The fact that oil and gas account for over four times the contribution of coal in annual energy consumed by industrial boilers suggests that a genuine opportunity exists to displace these fuels in quantity. Steam production, in particular, is one application where technology exists to burn coal, but a sustained conversion to coal is not taking place. To make coal combustion more acceptable and less expensive to industry, the development of packaged coal-fired systems should be of high priority. Fluidized bed coal combustion (FBC) can perhaps satisfy this need, chiefly because its improved heat transfer characteristics effectively shrink the furnace volume. Furthermore, if the bed is operated under pressure, then another size reduction is realized. A preliminary study of the feasibility of packaging coal-fired fluidized bed boilers for industry was performed by the Oak Ridge National Laboratory (ORNL). The study focused on and compared atmospheric fluidized beds (AFB) and pressurized fluidized beds (PFB). The PFB boiler module appears to have potential for packaging, while the AFB boiler was found to have some inherent characteristics that may jeopardize its potential as a packaged system in the same size range. A conceptual cost estimate is presented with an economic assessment that brings into perspective the impact that development of large coal-fired packaged-boilers could have on the use of oil and gas in industry. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6h41v08 |

| Setname |

uu_afrc |

| ID |

3490 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6h41v08 |