| Title |

Combustion Modifications for Coal-Fired Stoker Boilers |

| Creator |

Maloney, K. L. |

| Publisher |

University of Utah |

| Date |

1982 |

| Spatial Coverage |

presented at Newport Beach, California |

| Abstract |

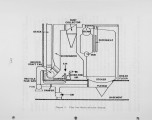

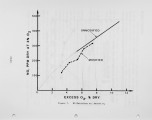

Stoker boilers suffer from poor operating efficiency and inadequate air emission control to be attractive in today's market. They are however relatively inexpensive to purchase and can operate on inexpensive fuel. The work presented in this paper shows how the stoker boiler can have its fuel efficiency improved and the emission of particulate matter, nitrogen oxides (NOx), and sulfur oxides (SO ) reduced. These combustion modifications should make the stoker boiler the coalfired combustion system of choice for the industrial client. KVB has applied for and received a U.S. patent (No. 4,335,660) covering the Stoker Gas Recirculation systems that are discussed in this paper. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6w95cr0 |

| Setname |

uu_afrc |

| ID |

3424 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6w95cr0 |