| Title |

The Combustion of a Fuel Mixture Composed of Coal and Light Fuel Oil |

| Creator |

Cundy, V. A. Ph.D.; Maples, D. Ph.D.; Burch, T. M.S. |

| Publisher |

University of Utah |

| Date |

1983 |

| Spatial Coverage |

Akron, Ohio |

| Abstract |

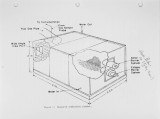

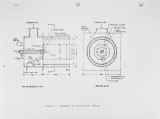

The development of alternative fuels at the industrial and utility level has expanded dramatically since the 1973 oil embargo. The increasing efforts directed toward the development of the coal-oil technology are clear evidence of this thrust. This paper reports on research directed toward demonstrating the viability of coal-No. 2 fuel oil mixtures as a suitable conventional fuel replacement in existing combustors. The paper is devoted to combustion characteristics of these fuel mixtures and does not report on fouling characteristics, corrosion or errosion phenomena, or pollution characteristics. Fuel mixtures at the 50 weight percent coal loading level in No. 2 fuel oil are studied for a number of coal types. Results indicate that the fixed carbon of the parent coal is most important in determining the optimum coal to be used in the mixture for maximum combustion efficiency. Of secondary importance is the coal size which is directly related to fuel viscosity. A complete discussion of the fuels used, the combustion facility, and the results obtained are provided in the paper. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6cz39pd |

| Setname |

uu_afrc |

| ID |

300 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6cz39pd |