| Title |

Development and Demonstration of the Radiation Stabilized Burner for Boilers and Process Heaters |

| Creator |

Sullivan, John D.; Webb, Andrew W. |

| Publisher |

University of Utah |

| Date |

1996 |

| Spatial Coverage |

presented at Baltimore, Maryland |

| Abstract |

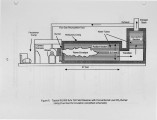

Alzeta has improved the performance of the Pyromat eSB burner, originally developed as a 30 ppm NOx burner for oil field steamers, by combining downstream fuel injection with lean premixed first-stage combustion. This advanced Radiation Stabilized Burner is the first industrial surface combustion burner to use fuel staging to lower pollutant emissions. By creating a secondary flame envelope around the lean, premixed primary burner, Alzeta has achieved NOx emissions of 10-20 ppm and CO emissions below 50 ppm while operating at 3% stack oxygen in a 50,000 Ib/hr oil field steamer. Initial development of the Radiation Stabilized Burner was completed in a 3 MMBtu/hr water tube boiler where the effect of secondary fuel injection on NOx emissions was experimentally determined. Parameters such as fuel flow rate, injection angle, and velocity were optimized to achieve NOx and CO emissions below 9 ppm at low stack oxygen levels. The burner was then scaled up for the first industrial-scale test in an oil field steamer. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s64x5bdg |

| Setname |

uu_afrc |

| ID |

13233 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s64x5bdg |