| Title |

Pilot Scale Studies on PCDD/PCDF Formation and Control Using the Strategic Cofiring of Natural Gas in Municipal Waste Combustion Systems |

| Creator |

McGrath, T. P.; Seeker, W. R.; Chen, S. L.; Linz, D. G. |

| Publisher |

University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

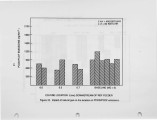

This test program was designed to study the formation and emission of PCDD/PCDF during Refuse Derived Fuel combustion. Tests were conducted in a pilot scale RDF incinerator. Incinerator fly ash hold up for one hour at a temperature of 570F resulted in an 8 to 20 fold increase in PCDD/PCDF content. Reductions in RDF load were found to decrease PCDD/PCDF emissions. Fluctuations in RDF feed rate produced increases in PCDD/PCDF emissions. Test results suggest the dominant PCDD/PCDF formation mechanism(s) in the incinerator involve organic compounds in entrained fly ash. A combustion strategy for PCDD/PCDF emissions control has been developed. Natural gas co-firing allows RDF load reduction while smoothing temporal and spatial fluctuations in the furnace. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6zc85fx |

| Setname |

uu_afrc |

| ID |

6398 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6zc85fx |