| Title |

Combustion Evaluation of Advanced Coal Cleaning Products: Test Program and Initial Results |

| Creator |

Smouse, Scott M.; McIlvried, Timothy S. |

| Publisher |

University of Utah |

| Date |

1988 |

| Spatial Coverage |

presented at Pittsburgh, Pennsylvania |

| Abstract |

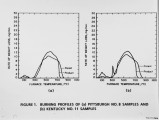

Advanced coal preparation processes have the potential to allow the low-cost production of deeply beneficiated coals. To gain the acceptance of the utility and industrial boiler designers and operators, a detailed analysis of the combustion properties of beneficiated coal-based fuels, prior to full-scale production, is warranted. A multilevel evaluation of such fuels is under way at the DOE's Pittsburgh Energy Technology Center. The test program is described and initial resul ts for two chemically cleaned coals and three physically cleaned coals are presented. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6xw4nc5 |

| Setname |

uu_afrc |

| ID |

4645 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6xw4nc5 |