| Title |

Dense Phase Pneumatic Transport: An Alternative for Conveying Pulverized Coal |

| Creator |

Smith, D. A.; Lexa, G. F. |

| Publisher |

University of Utah |

| Date |

1982 |

| Spatial Coverage |

presented at Newport Beach, California |

| Abstract |

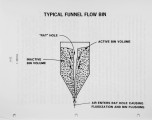

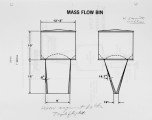

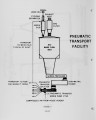

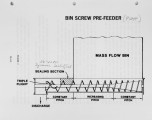

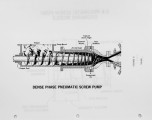

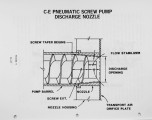

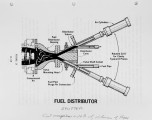

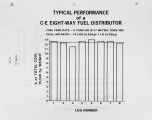

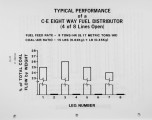

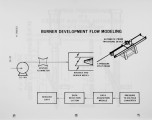

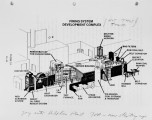

The concept presented is an integrated system designed to supply pulverized coal to multiple end use points (usually burners) in a consistent uniform stream which can be modulated as required to meet changes in load demand. The differences between conventional dense phase transport used for normal bulk solids transport and this modified dense phase system are discussed in detail. Detailed process flow schematics and descriptions of key equipment are also included. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6pr7zjq |

| Setname |

uu_afrc |

| ID |

3092 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6pr7zjq |