| Title |

Energy Recovery From the Combustion of Wastes in the Multisolid Fluidized Bed Combustor |

| Creator |

Lisauskas, Robert A.; Breault, Ronald W. |

| Publisher |

University of Utah |

| Date |

1987 |

| Spatial Coverage |

presented at Palm Springs, California |

| Abstract |

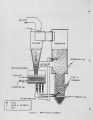

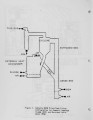

Circulating fluidized bed combustion processes have demonstrated successful destruction of wastes in an environmentally acceptable manner. Multisolid Fluidized Bed Combustion (MSFBC) is one circulating fluidized bed system which is particularly suited for waste disposal with energy recovery. Several pilot and commercial size MSFB systems have demonstrated the ability to successfully cofire waste streams such as: paint sludges, municipal RDF, wood waste and coal mine waste. Several commercial MSFB boilers have been designed to dispose of manufacturing wastes such as plastics and paint sludge. The disposal of refinery waste streams is also being investigated. This paper describes the MSFB technology and various system configurations for drying, combustion, and conversion of the waste streams into useful energy. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6mk6gg9 |

| Setname |

uu_afrc |

| ID |

4319 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6mk6gg9 |