| Title |

A Numerical Study of the Effects of Biomass Coal Cofiring on Unburned Carbon and NOx Emissions |

| Creator |

Gera, D.; Mathur, Mahendra P.; Freeman, Mark C.; Robinson, Allen L. |

| Publisher |

University of Utah |

| Date |

1999 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

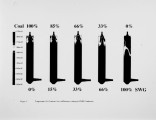

A biomass particle combustion model is developed and implemented in the commercial computational fluid dynamic code FLUENT to examine the effects of cofiring biomass and coal on unburned carbon and NOx emissions in a pilot scale pulverized fuel combustor. The coal/biomass combustion is simulated using the two-mixturefraction, probability density function (PDF) approach and finite rate chemistry formulation. The coal devolatilization is simulated using the two-competing-rates Kobayashi model, and the char oxidation is modeled as the kinetics controlled surface reaction. The biomass devolatilization is incorporated using an Arrhenius-type, first order kinetic rate model. The biomass char oxidation is controlled by diffusion-limited surface reaction, and it is modeled as a constant density process. Model predictions were found to be in reasonably good agreement with the experimental data from the Sandia National Laboratory's Multifuel Combustor. Some exploratory simulations are also performed to predict the unburned carbon and NOx emissions in the CERF, a pilot scale 150 kW, combustor at the Federal Energy Technology Center. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6j968zq |

| Setname |

uu_afrc |

| ID |

12621 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6j968zq |