| Title |

Effect of Fuel Structure on Oxygenated Aromatic Species in a Premixed Flat Flame |

| Creator |

Tumati, Prasad R.; Partridge, Patricia A.; Cernansky, Nicholas P.; Cohen, Richard S. |

| Publisher |

University of Utah |

| Date |

1985 |

| Spatial Coverage |

presented at Livermore, California |

| Abstract |

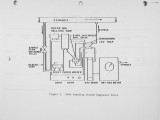

The oxygenated aromatic hydrocarbon species, along with other moderately polar components within diesel exhaust, have been found to be responsible for the characteristic odor, irritation and mutagenicity of the diesel exhaust. Various researchers have reported contradictory effects of fuel properties on the emission levels of these species in both diesel engine and spray burner experiments. Much of this contradiction is probably due to close interrelationships and dependencies of various fuel properties and from difficulties in isolating the various physical and chemical phenomena in these systems. In the present study, a premixed prevaporized flat flame was used to eliminate most of the complicating phenomena and focus exclusively on the chemical properties of various fuels. The fuels used were pure paraffins and aromatics. There were no significant differences ii the overall axial concentration profiles of oxygenated aromatic species in the flame and post flame zones for fuels within the same class. However, in general, aromatic fuels produced higher concentration levels of oxygenated aromatic species relative to paraffinic fuels. GC/MS analysis of selected samples indicated that all of the straight chain paraffins (octane, decane and dodecane) produced essentially similar oxygenated compounds. These fuels when oxidized formed small substituted one ring structures and some straight chain oxygenates that are relatively low in molecular weight. However, the oxidation of iso-octane (a branched paraffin) differed from that of n-octane oxidation. Several multi-ring structures like cinnoline and naphthalene derivatives were found during the oxidation of iso-octane, suggesting that two iso-octane compounds unite and rearrange to form these products. Similar analyses of aromatic fuels (Aromatic-150, toluene and tetralin) indicated that, in general, fuels with higher aromaticity are easier to partially oxidize. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6ff3vw5 |

| Setname |

uu_afrc |

| ID |

2265 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6ff3vw5 |