| Title |

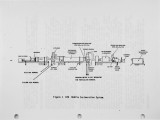

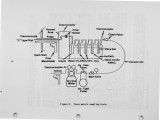

The Fate of Heavy Metals in EPA's Mobile Incineration System |

| Creator |

Stumbar, James P.; Sawyer, Robert H.; Gupta, Gopal D.; Perdek, Joyce M.; Freestone, Frank J. |

| Publisher |

University of Utah |

| Date |

1989 |

| Spatial Coverage |

presented at Short Hills, New Jersey |

| Abstract |

During the past year, the EPA Mobile Incineration System (MIS), has processed a brominated sludge material, which had significant concentrations of chromium and trace quantities of other heavy metals. A series of analytical tests were conducted on the MIS to ascertain the fate of these metals. Concentrations of these metals were measured in the stack, the waste feed, and the residue streams consisting of kiln ash, cyclone ash, separator sludge, and process water. Particle size distributions of all residue streams were also obtained and the lead concentration in each particle size range for each solid residue stream was obtained by Computer Controlled Scanning Electron Microscopy (CCSEM). The tests showed the following. Mercury did not appear in the kiln or cyclone ash in measurable quantities and was probably volatilized. A small amount of mercury was captured by the air pollution control train and it appeared in the stack in significant concentrations. Most of the lead and cadmium were volatilized and, after condensation, were contained in the separator sludge. Furthermore, the concentrations of lead, cadmium and mercury in the separator sludge and the stack were an order of magnitude higher than in the other solid streams. Total chromium concentrations were approximately the same in all solid streams but significant levels of hexavalent chromium were found only in the cyclone ash. The mechanisms controlling these phenomena are discussed in the paper. The health risk impacts of the metals emissions from the stack were evaluated in accordance with the latest EPA proposed guidelines. The emissions from the MIS were found to meet the proposed limits. This is an abstract of a proposed presentation and does not necessarily reflect EPA policy. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6cr5wx8 |

| Setname |

uu_afrc |

| ID |

5566 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6cr5wx8 |