| Title |

Velocity Measurements on Isothermal Sudden Expanding Swirling Flow in an Industrial Burner With Bluff-Body |

| Creator |

Yang, Shyh-Ching; Juang, Ruey-Shin; Chang, Wen-Chen; Chen, Jen-Shien |

| Publisher |

University of Utah |

| Date |

1989 |

| Spatial Coverage |

presented at Short Hills, New Jersey |

| Abstract |

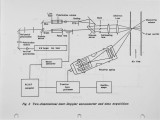

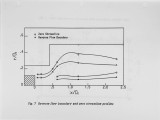

This paper describes two-dimensional back-scatter laser-Doppler anemometer mesurements in confined isothermal and nonreactiog sudden expanding swirling air flow. A swirling air flow, with an inlet swirl number of 2.0 is generated by an axial vane swirl generator. The swirling f1ow enters a 0.4 m diameter, 4 m long cylindrical chamber via a sudden expansion quarrel. The confine ratio equals to 2.1. The blockage ratio of the bluff-body equals to 0.5. The Reynolds number of the air is 5.0 x 10^4. Simultaneously axial and · azimuthal, mean and fluctuating velocity measurements were made by using laser-Doppler anemometer (LOA) system. It is found that the maximum reverse-flow rate occurs at about 0.50 furnace diameter with 60% of the inlet mass flow recirculated. Some quantitative information, such as the size, shape and the intensity of the central recirculation zone, axial distribution of energy flux were provided. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6474dd1 |

| Setname |

uu_afrc |

| ID |

5609 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6474dd1 |