| Title |

Coal-Water Mixture Combustion and Flame Studies at TRW |

| Creator |

Roy, Dr. Gabriel ; Albright, Jack |

| Publisher |

University of Utah |

| Date |

1983 |

| Spatial Coverage |

Akron, Ohio |

| Abstract |

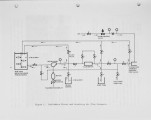

Coal-water mixture (CWM) atomization and combustion characteristics were investigated. The results of this investigation show promise for using CWM as a fuel for retrofit in utility and industrial applications, and demonstrated the adaptability of the TRW coal combustor for CWM combustion. A 10 MM Btu/hr burner was developed and its geometry optimized after thorough cold-flow atomization studies. Combustion studies were carried out in a 17-inch slagging coal combustor at the TRW Fossil Energy Test Site (FETS) using CWM manufactured by the Atlantic Research Corporation (ARC). The effect of various parameters on combustion and flame stability was investigated. It was demonstrated that heavily loaded (70%) CWM can be burned with a stable flame over a wide range of stoichiometry (0.7 < <f> < 1.15) and preheat temperature (700 F < T < 1900 F) in the TRW slagging combustor. The burner designed for 10 MM Btu/hr rating operated well up to 15 MM Btu/hr and could be derated down to 5 MM Btu/hr indicating a wide load range. No flow, control or hardware related problems were experienced. Furthermore, the CWM did not cause any plugging or settling problems. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s60p12js |

| Setname |

uu_afrc |

| ID |

399 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s60p12js |