| Title |

Reduction of Nitrogen Oxides Emissions by Combustion Process Modification in Natural Gas Flames: Fundamentals of Low-NOx Burner Design |

| Creator |

Toqan, M. A.; Berg, L.; Beer, J. M.; Marotta, A.; Beretta, A. |

| Publisher |

Digitized by J. Willard Marriott Library, University of Utah |

| Date |

1990 |

| Spatial Coverage |

presented at San Francisco, California |

| Abstract |

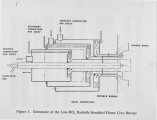

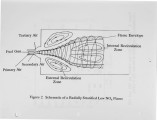

Increasingly tight environmental regulations for NOx emission from coal-, oil- and gas-fired utility boilers are urging utility and industrial users of fossil fuels to pay greater attention to control of NOx in oil, coal and even gas-fired units. Effective control of NOx emissions requires the application of one or a combination of methods of combustion process modification including staged air and staged fuel injection, the use of 10w-NOx burners, and possibly even post-combustion clean-up such as NH3 injection into combustion gases. To date, the degree of NOx reduction achieved by these technologies has been observed to vary widely and to depend on the combustion system in question. This wide variation in performance of staged systems and of 10w-NOx burners is due primarily to lack of understanding of the overlapping processes of the nitrogen-hydrocarbon chemistry and the mixing-temperature history of the fuel in the flame. To address the variation of performance of 10w-NOx burners an experimental investigation is being carried out at MIT which is focused on the fundamentals of lowNOx burner design, applied to natural gas and oil. A novel type multi-annular burner based on Beer's patented design and further developed at MIT is used in experimental studies. The experiments are carried out using the 1.2 x 1.2 x 4.5 test section of the MIT Combustion Research Facility (CRF). The CRF has a multi-fuel firing capability with a thermal input of up to 3 MW. It is equipped with optical and probing devices to permit detailed investigations to be made of the variation of combustion properties in industrial type turbulent flames. The experimental burner consists of a central fuel gun surrounded by three annular air nozzles. Both the distribution of the air flow and degree of air swirl are controlled independently in the three annuli. The highly flexible experimental burner permits the variation of fuel mixing history over wide ranges. Initial results show that NOx reduction of about 75% (from 240 ppm to 60 ppm) can be achieved by varying fuel-air mixing in a manner that would stratify the flame radially in the near field of the burner but permit full mixing further downstream to yield complete combustion with 2% O2 in the stack. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s66112v4 |

| Setname |

uu_afrc |

| ID |

5924 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s66112v4 |