| Title |

Sulfur and Nitrogen Devolatilization From Pulverized Coal in an Opposed-Flow Diffusion Flame |

| Creator |

Zghoul, Ali M.; Grosshandler, William L. |

| Publisher |

Digitized by J. Willard Marriott Library, University of Utah |

| Date |

1985 |

| Spatial Coverage |

presented at Livermore, California |

| Abstract |

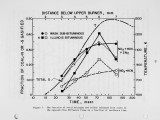

The devolatilization of a low-sulfur subbituminous and a high sulfur bituminous coal, pulverized to a mass-mean diameter of 12 nm, has been studied in an opposed-flow diffusion flame. The flame structure of the rectangular burner has been determined using different propane/coal/argon/ oxygen mixtures. The temperature and major species concentration measurements indicate that gradients perpendicular to the coal/propane flame front are much greater than those parallel to it. The coal particles have been exposed to heating rates between 2000 and 20,000 K/s as they enter the flame, reaching a peak temperature around 1,500 K. The evolution of gaseous nitrogen (HCN, NO, NOx and N2 ) and sulfur (SO2, SO3, H2S, COS, and CS2) species has been followed as a function or position in the flame. The maj or nitrogen species released from the bituminous coal was HCN, with a peak of 130 ppm 60 msec after entering the flame. A maximum of 55 ppm N was formed during devolatilization. The subbituminous coal produced only one-fifth the HCN levels. but the molecular nitrogen was greater. even though coal-bound nitrogen made up about 0.8% of the mass of each coal. The total fraction of char nitrogen released was between 34 and 40% for both coals. After an initial preheating period, the devolatilization rate of each coal was approximately 1% char-N per msec during the first 70 msec in the flame zone. Replacing the argon diluent gas with N2 increased the NOx by a factor of three and the HCN 30-fold. Sulfur is released early in the flame. primarily as SO2 , but a significant portion of 502 is destroyed just after passing through the hot test part of the "flame. This coincides with the maximum concentration of SO3 (50 ppm) which makes up 12% of the SOx at this point in the high sulfur bituminous coal/propane/oxygen/argon flame. This coal releases one third of its bound sulfur during the 100 ms transit time through the diffusion flame. while the low sulfur subbituminous coal releases only 10% of its bound sulfur under identical flame conditions. A possible explanation for the different behavior is the much higher calcium-to-sulfur ratio in the subbituminous coal, resulting in higher sulfur-retention. The behavior of the nitrogen and sulfur in the coal-doped diffusion flames is compared to published results of premixed flat flame and tunnel reactor experiments. |

| Type |

Text |

| Format |

application/pdf |

| Language |

eng |

| Rights |

This material may be protected by copyright. Permission required for use in any form. For further information please contact the American Flame Research Committee. |

| Conversion Specifications |

Original scanned with Canon EOS-1Ds Mark II, 16.7 megapixel digital camera and saved as 400 ppi uncompressed TIFF, 16 bit depth. |

| Scanning Technician |

Cliodhna Davis |

| ARK |

ark:/87278/s6nz8b5g |

| Setname |

uu_afrc |

| ID |

2420 |

| Reference URL |

https://collections.lib.utah.edu/ark:/87278/s6nz8b5g |